From simple beginnings as a bone stock 2003 Hyundai Elantra, to unique mutant vehicle… We removed the roof, doors and door pillars to allow a more flexible base.

After driving the car around for about 20 minutes with no roof and doors it became VERY apparent that once you remove major structure from a unibody car, you do in fact end up with a wet noodle… as much fun as it was, I decided that putting in at least ONE brace might not be a bad idea before I proceeded any further.

After driving the car around for about 20 minutes with no roof and doors it became VERY apparent that once you remove major structure from a unibody car, you do in fact end up with a wet noodle… as much fun as it was, I decided that putting in at least ONE brace might not be a bad idea before I proceeded any further.

All of the square tube shown here is 1″ .125 wall, bent in house on our JD Squared Model 53 rotary bender

All of the square tube shown here is 1″ .125 wall, bent in house on our JD Squared Model 53 rotary bender

One of the biggest problems I noticed about a lot of mutant vehicles is that the driver is either completely isolated, or TOO in the fray… I made sure that the singe entry and exit point is easy for the driver to see and control, while having a definite buffer zone around the operating area ensured.

One of the biggest problems I noticed about a lot of mutant vehicles is that the driver is either completely isolated, or TOO in the fray… I made sure that the singe entry and exit point is easy for the driver to see and control, while having a definite buffer zone around the operating area ensured.

Through extensive testing and pure dumb luck, I managed to find the perfect bend for a seat-back… these are 1/2″ square tube, also bend in-house… there are 136 of these tubes that make up the bench seat in Slag.

Through extensive testing and pure dumb luck, I managed to find the perfect bend for a seat-back… these are 1/2″ square tube, also bend in-house… there are 136 of these tubes that make up the bench seat in Slag.

It always starts with one! My roundabout jig, actually worked out perfectly… for what it was.

It always starts with one! My roundabout jig, actually worked out perfectly… for what it was.

I would love to say the whole thing picked up a rhythm and went quickly, but the actual length of square and straight pieces is slim… needing quite a bunch more attention to achieve what I was going for.

I would love to say the whole thing picked up a rhythm and went quickly, but the actual length of square and straight pieces is slim… needing quite a bunch more attention to achieve what I was going for.

At this point I actually had a neighbor stop by and ask why I was building a cattle feeder out of a Hyundai… Ive learned to just go with it here in rural Texas, its just easier.

At this point I actually had a neighbor stop by and ask why I was building a cattle feeder out of a Hyundai… Ive learned to just go with it here in rural Texas, its just easier.

Here Im getting a rough fit before its back to the bender again… I COULD have just made straight sides… but what fun is THAT to try and replicate on a bender?

Here Im getting a rough fit before its back to the bender again… I COULD have just made straight sides… but what fun is THAT to try and replicate on a bender?

Drivers side top tube on… the top tube is actually just 3/4″ pipe, which is considerably stronger than one might think. Would I want to make a roll cage out of it, ummm no…

Drivers side top tube on… the top tube is actually just 3/4″ pipe, which is considerably stronger than one might think. Would I want to make a roll cage out of it, ummm no…

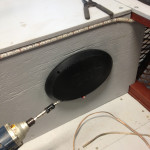

One of the key features to Slag, is that there is only one entry/exit point, and as you can see, in clear view of the driver.